Hydrogen bunkering station

Baltic's First Green Hydrogen Electrolyser to produce green hydrogen

A new hydrogen refuelling station at the Port of Klaipėda in Lithuania, to be developed by MT Group will be equipped with a PEM electrolyser . This will be the the first in the Baltic region to produce green hydrogen on-site.

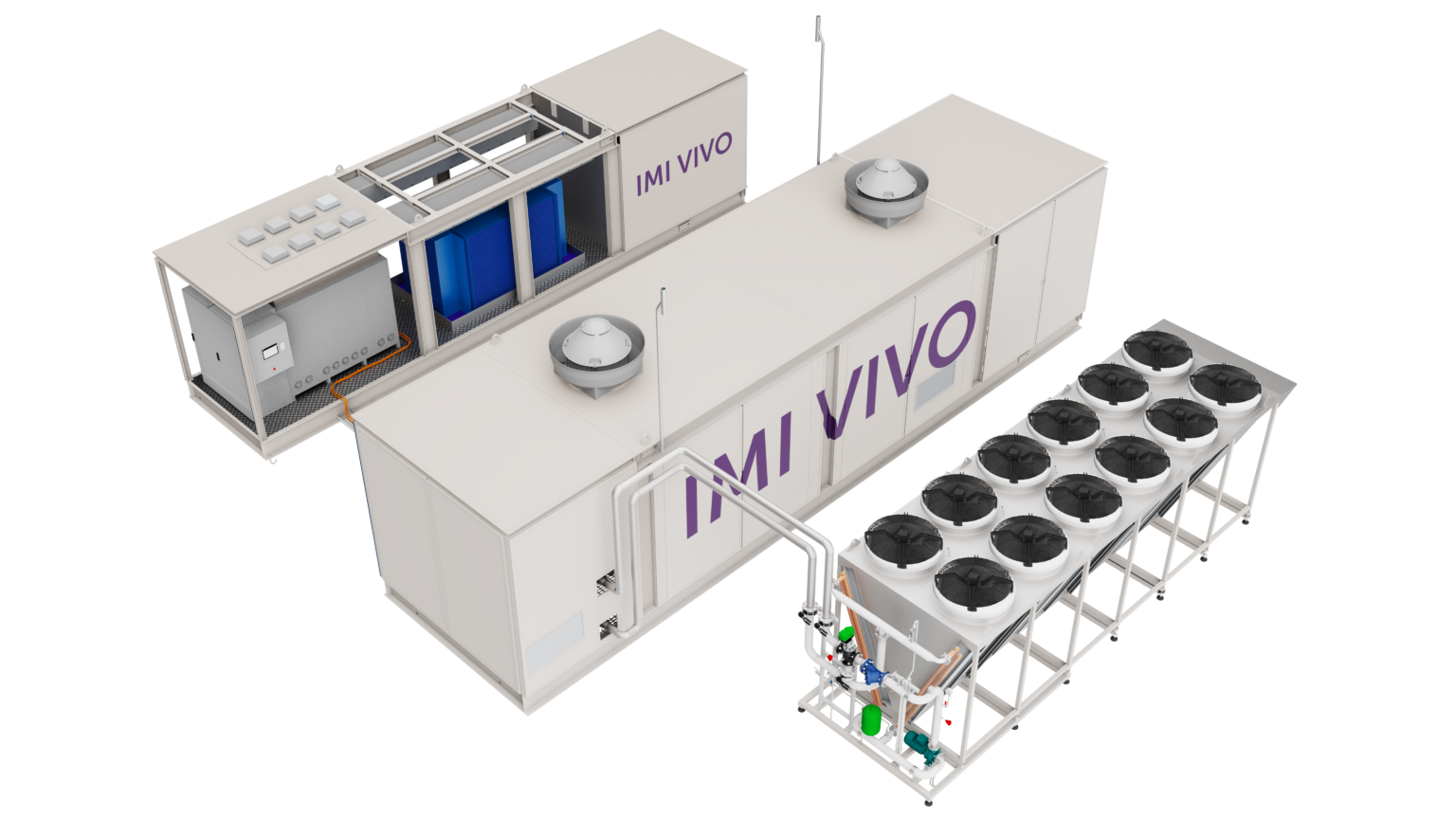

The IMI VIVO electrolyser will enable the port, which is the second largest EU port by tonnage in the Baltic, to produce 500kg of green hydrogen on-site per day. This is equivalent to 127 tons per year while using an electrical input of 3 MW, drawn from sustainable sources. On-site production helps to reduce the need for transportation and storage of hydrogen, while also reducing associated emissions.

IMI’s VIVO Electrolyser offers full customisation in size, capacity, and configuration, ranging from 100kW to 5MW, with potential for further expansion to 20MW through a modular configuration.

Mauro Natalini, Sales & Business Development Manager at IMI, said: “Electrolysers can provide huge benefits to the marine sector, and help to meet the stringent targets set out by the EU as part of the European Green Deal.”

Mindaugas Zakaras, CEO of MT Group, said: “As part of our vision to encourage sustainability, we are committed to making the new hydrogen refuelling station in Klaipda a benchmark for the entire industry. This will be achieved by using the most innovative technology to maximise capacity while meeting the highest quality and safety standards.

Tracing hydrogen

Hydrogen producer Lhyfe has joined forces with Atmen to become the 1st player in the hydrogen sector to guarantee the traceability of its green and renewable hydrogen, a major step towards its ‘RFNBO*’ certification.

Lhyfe is a European group devoted to energy transition, and a producer and supplier of green and renewable hydrogen. Its production sites and portfolio of projects seek to provide access to green and renewable hydrogen in industrial quantities, and enable the creation of a virtuous energy model capable of decarbonising entire sectors of industry and transport.

Each delivery of green and renewable hydrogen from Lhyfe can now include a Digital Product Passport, offering buyers full transparency on the origin of the hydrogen produced, the carbon footprint of its production and, soon, an “RFNBO-compliant” label proved through Atmen’s automated compliance and traceability platform.

Antoine Hamon, Chief Operations Officer at Lhyfe: “Our collaboration with Atmen is a major step in realising our commitment to transparency for our clients, both in terms of sustainability and traceability. With Digital Product Passports, we are enhancing trust in the sustainability of our hydrogen. We invite the sector to align with this practice, which will help develop the industry with the same spirit of trust.”

Lhyfe’s other projects include the “first industrial-scale green hydrogen production plant in the world to be interconnected with a wind farm” in 2021. In 2022, it inaugurated the first offshore green hydrogen production pilot platform. In 2023, it inaugurated two new sites, and currently has several sites under construction or expansion across Europe.

25/02/2025

Image Caption: IMI VIVO Electrolyser

Image Credit: IMI

get

in touch

Constructive Media

Constructive Media

Hornbeam Suite

Mamhilad House

Mamhilad Park Estate

Pontypool

NP4 0HZ

Tel: 01495 239 962

Email: ibia@constructivemedia.co.uk

On behalf of:

IBIA London Office

Suite Lu.231

The Light Bulb

1 Filament Walk, Wandsworth

London, SW18 4GQ

United Kingdom

Tel: +44 (0) 20 3397 3850

Fax: +44 (0) 20 3397 3865

Email: ibia@ibia.net

Website: www.ibia.net

Emails

Publisher & Designer: Constructive Media

ibia@constructivemedia.co.uk

Editor: David Hughes

anderimar.news@googlemail.com

Project Manager: Alex Corboude

alex@worldbunkering.net