Mitigating FuelEU Maritime challenges

Service providers move to support shipowners navigate new EU regulations

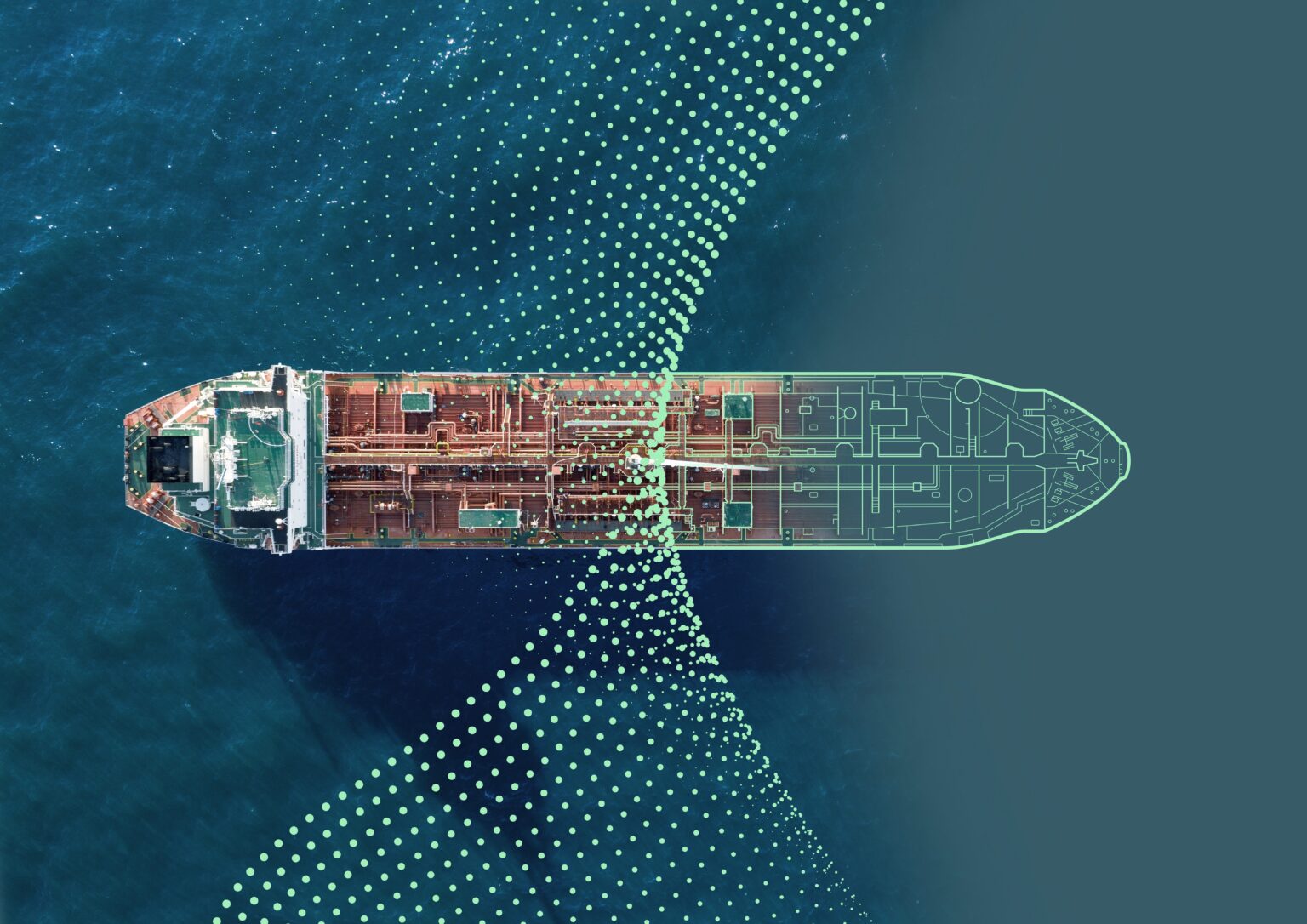

DNV has announced an upgrade to its emissions data verification and data management platform, Emissions Connect, which will enable the maritime sector to handle the commercial challenges and risks that come with the implementation of FuelEU Maritime.

FuelEU Maritime sets limits on the greenhouse gas (GHG) intensity of fuels used by ships calling at EU ports and progressively reduces these levels towards 2050. The regulation covers well-to-wake emissions from the entire fuel life cycle and requires ship managers to submit a monitoring plan, report emissions data annually and have their compliance balance verified. GHG intensity which is too high can lead to a negative balance, which, if not compensated in a pool with other ships, will trigger a penalty that the shipping company must pay to the national authorities.

The Norwegian classification says its platform was first launched in 2023 “to support the industry with the operational impact of multiple regulatory requirements and decarbonisation trajectories. Specifically, it helps the industry manage and control Carbon Intensity Indicator (CII) performance, manage the commercial obligations arising from the European Union’s (EU’s) Emissions Trading System (ETS) and now also the implications of FuelEU Maritime”.

Pål Lande, Product Line Director, DNV Maritime said: “The introduction of new regulation to drive decarbonisation is creating a complex environment for organisations across the shipping sector. To assist companies in dealing with this change, we are pleased to be offering a solution that will help them manage the commercial impact of these new rules and collaborate across the supply chain. Accurate and verified data is crucial to instil trust and ensure effective collaboration within this complex environment.”

Meanwhile New York-based software-as-a-service company OrbitMI says it is now providing advanced data-driven tools “to effectively navigate the complex regulation together with partner Bureau Veritas (BV)”.

The latest EU regulation, coming on the heels of the EU ETS, entails new operational challenges as vessel operators must carefully manage and monitor their fuel mix across voyages to optimise compliance and minimise penalties for non-compliance with GHG intensity reduction targets.

OrbitMI CEO Ali Riaz says: “Companies trading in the EU need to understand the regulation and adapt their operations to FuelEU as the clock ticks to implementation in 2025. His company, together with? BV Marine & Offshore, has enhanced its Orbit vessel performance platform for FuelEU planning and monitoring to optimise operations, while facilitating data management and collaboration for efficient regulatory compliance.

According to OrbitMI, the collaborative platform allows seamless communication between stakeholders to ensure decisions affecting FuelEU compliance are visible to all parties. It asserts: “By providing visibility into the vessel’s itinerary, position, daily fuel consumption and weather conditions, both the vessel owner and operator can avoid post-voyage surprises and take decisions that minimise or eliminate penalties.”

Permanent magnet shaft generators for LNG carriers

Technology company ABB is to equip 15 LNG carriers being built at Samsung Heavy Industries with the permanent magnet shaft generator technology. The 174,000 cubic metre capacity ships are due for delivery between mid-2026 and August 2028 to multiple leading owners serving the supply chain needs of charterer Qatar Energy.

ABB says its permanent magnet shaft generator technology enhances operational efficiency of vessels by utilising the power from the shaft and main engine, resulting in better fuel economy compared to getting the power from high-speed, fuel-intensive auxiliary engines.

In addition, it says, the permanent magnet shaft generator is optimised for converter control, enabling better efficiency than either induction or electrically excited synchronous machines can offer at full and partial load. According to ABB’s estimation, this helps to cut ship fuel costs by up to 4%. Working with ABB’s advanced ACS880 Converter and Control System with D/C Link, the technology can increase fuel efficiency by a further 1%.

“The scale of this order suggests that key LNG stakeholders now recognise permanent magnet shaft generator system benefits that are widely accepted by owners in the container ship, oil tanker and bulk carrier markets,” says Michael Christensen, Global Segment Responsible for Cargo, ABB Marine & Ports.

Image Caption: DNV Emissions-Connect Visual

20/12/24

Image Caption: Data quality is a key factor for effective decision-making in maritime, says OrbitMI

Image Credit: 123RF

get

in touch

Constructive Media

Constructive Media

Hornbeam Suite

Mamhilad House

Mamhilad Park Estate

Pontypool

NP4 0HZ

Tel: 01495 239 962

Email: ibia@constructivemedia.co.uk

On behalf of:

IBIA London Office

Suite Lu.231

The Light Bulb

1 Filament Walk, Wandsworth

London, SW18 4GQ

United Kingdom

Tel: +44 (0) 20 3397 3850

Fax: +44 (0) 20 3397 3865

Email: ibia@ibia.net

Website: www.ibia.net

Emails

Publisher & Designer: Constructive Media

ibia@constructivemedia.co.uk

Editor: David Hughes

anderimar.news@googlemail.com

Project Manager: Alex Corboude

alex@worldbunkering.net